Hot Line

88910291

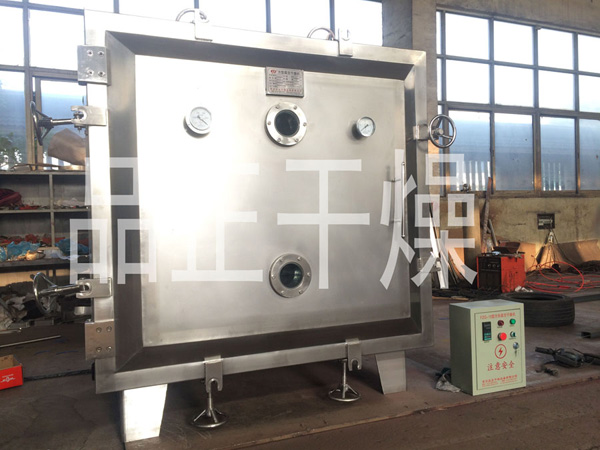

The electric heating vacuum drying oven supplied by Changzhou Pinzheng Drying Technology Co., Ltd. is the first choice of vacuum drying machine for products after Maillard reaction of food additives! Pinzheng electric heating vacuum drying oven is used by many complex seasoning customers in Zhuhai, Guangzhou and other places!

This type of electric heating vacuum drying oven has the advantages of (energy saving, high drying rate, convenient and simple operation, and saving production site)! Our manufacturing process is solid and reliable. The door and pressing flange are flat on a large planer, which can ensure the sealing performance of the door, enable the vacuum dryer to reach a higher vacuum, and greatly improve the quality of the products!

Working principle:

The so-called vacuum drying is to heat and dry the dry materials under vacuum conditions. If the vacuum pump is used for air extraction and dehumidification, the drying speed will be accelerated.

Note: If a condenser is used, the solvent in the material can be recovered through the condenser. If the solvent is water, the condenser can be used to save energy investment.

Performance characteristics:

◎The boiling point of the material solution under vacuum decreases, which increases the heat transfer impetus of the evaporator. Therefore, a certain amount of heat transfer can save the heat transfer area of the evaporator.

◎The heat source of evaporation operation can be low-pressure steam or waste heat steam.

◎Evaporator has less heat loss.

◎Disinfection can be carried out before drying, and there is no impurity contamination in the drying process, meeting the GMP requirements.

◎It is a static vacuum dryer, so the shape of the dried material will not be damaged.

Applicable materials:

Suitable for low-temperature drying of heat-sensitive materials that are easy to decompose, polymerize and deteriorate under high temperature; It is widely used in pharmaceutical, chemical, food, electronics and other industries.

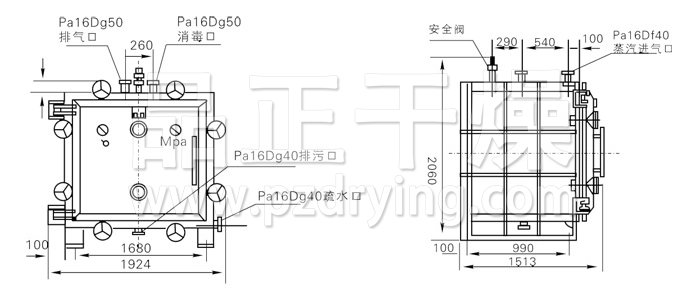

Structure diagram:

Technical specifications:

Name/specification | FZG-10 | FZG-15 | FZG-20 |

Size of drying box | 1500×1060×1220 | 1500×1400×1220 | 1500×1800×1220 |

External dimension of drying oven | 1513×1924×1720 | 1513×1924×2060 | 1513×1924×2500 |

Number of layers of drying rack | 5 | 8 | 12 |

Interlayer distance | 122 | 122 | 122 |

Oven size | 460×640×45 | 460×640×45 | 460×640×45 |

Number of baking plates | 20 | 32 | 48 |

Pressure in drying rack pipe | ≤0.784 | ≤0.784 | ≤0.784 |

Operating temperature of drying rack | 35-150 | 35-150 | 35-150 |

Empty vacuum degree in the box | -0.09~0.096 | ||

Water gasification rate at -0.1MPa and heating temperature of 110°C | 7.2 | 7.2 | 7.2 |

When using condenser, vacuum pump model and power | 2X-70A / 5.5KW | 2X-70A / 5.5KW | 2X-90A / 2KW |

Model and power of vacuum pump when condenser is not used | SK-3 / 5.5KW | SK-6 / 11KW | SK-6 / 11KW |

Weight of drying oven | 1400 | 2100 | 3200 |

Note: The water ring vacuum pump is combined with mechanical supercharging to improve the vacuum degree.

Ordering instructions:

◎When ordering, please select the appropriate vacuum dryer according to the physical properties, initial moisture content, final moisture content, temperature, vacuum degree, drying capacity, drying time and other factors. The vacuum dryer of the same model has four heating modes: steam hot water heat transfer oil electric heating. For example, in order to increase the drying capacity, the number of drying rack layers can be appropriately increased. Please report to our factory in time.

◎The accessories in the vacuum drying system mentioned above in the operating instructions can be provided and installed by our factory for users. Please specify when ordering.

◎Our company can provide design, manufacture and installation for special requirements in vacuum drying system put forward by users.

◎The equipment of our company implements three guarantees of quality for users. All accessories are provided for a long time. Please rest assured.